Our Previous Projects

Engineering solutions for automotive, mining, agriculture, heavy industry, and beyond. With our engineering accreditation, we can sign off on most projects, regardless of sector.

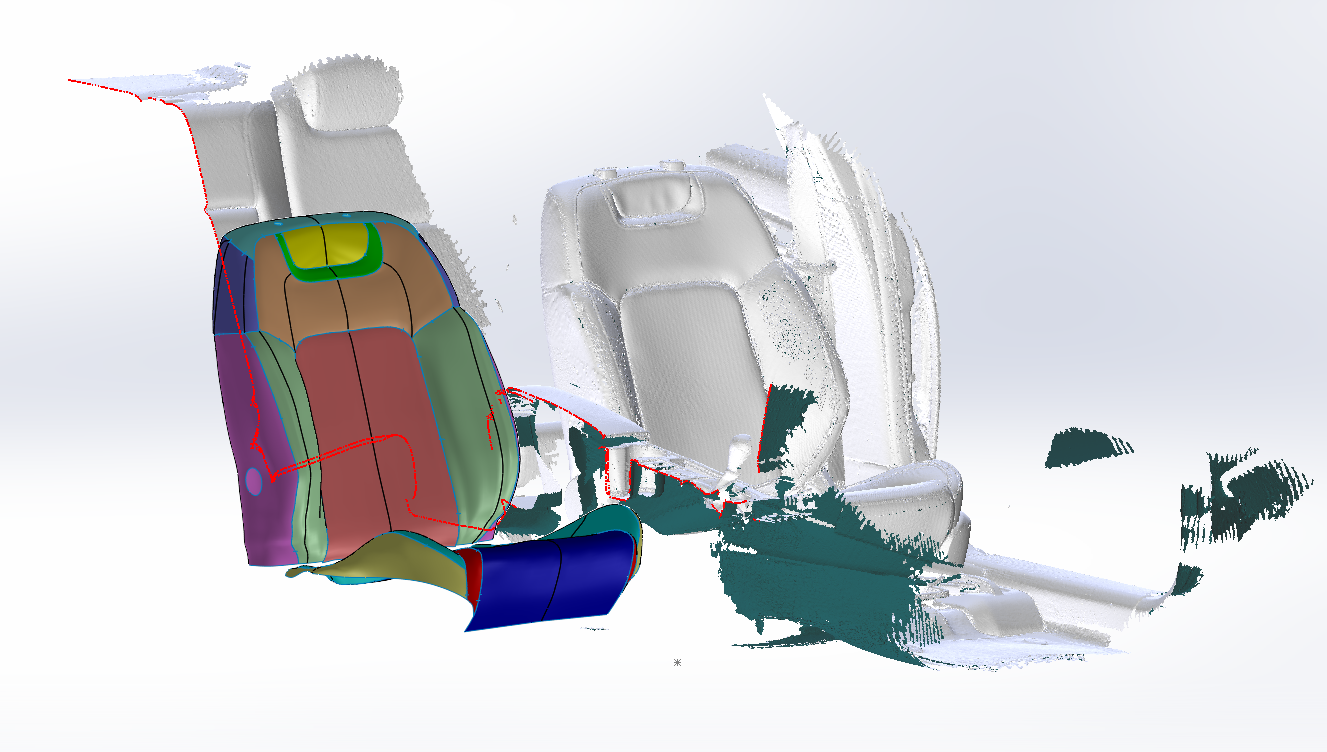

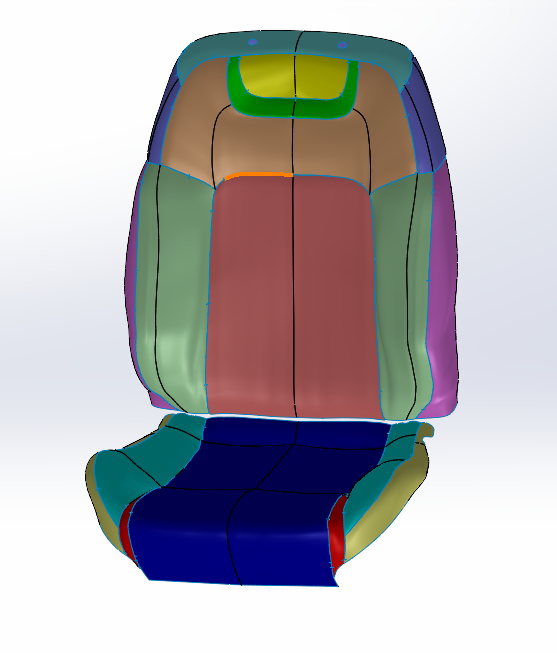

Car seat cover surfacing and pattern design

Using advanced 3D scanning and surfacing technology, we modernise the traditional process of car seat pattern making. Our team scans each seat, builds a clean digital surface model, and generates precision-cut patterns ready for laser cutting.

Benefits:

Up to 80% time reduction compared to manual hand templating

Perfect repeatability and high-accuracy digital patterns

Cleaner, sustainable workflow for trim shops and upholstery businesses

Eliminates human error and inconsistent templates

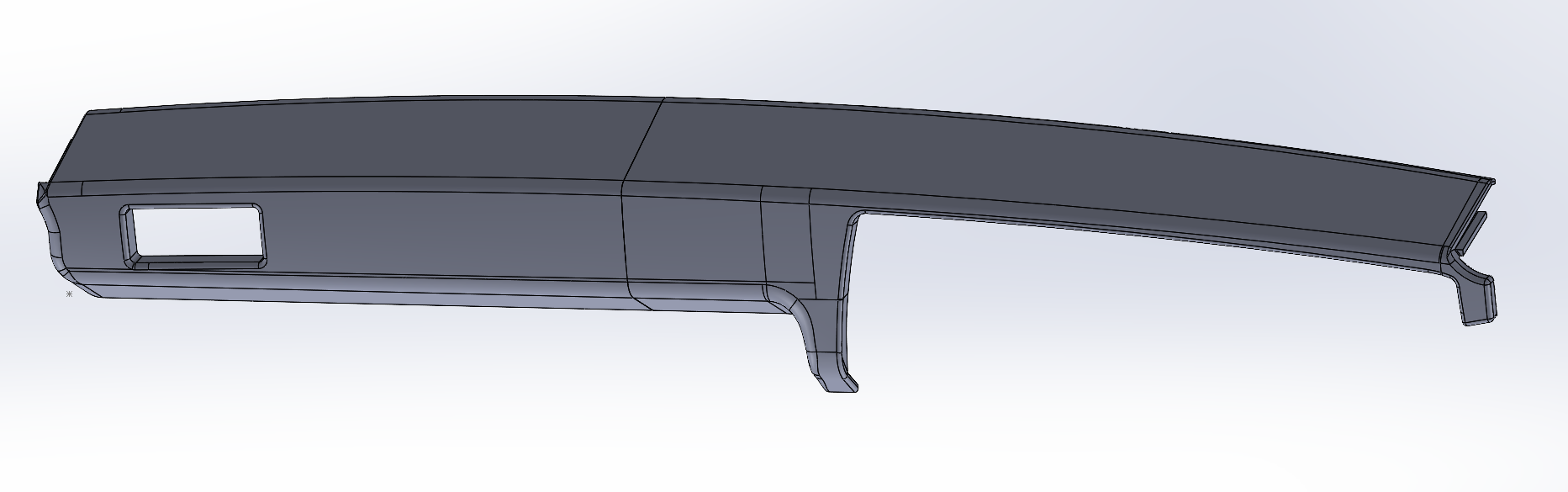

Parts Manufacturing – Classic & Modern Vehicles

Our clients often spend countless hours restoring old dashboards and interior components. Babylon Engineering solves this by supplying brand-new, precision-manufactured parts that fit perfectly and can be delivered within 48 hours.

What we deliver:

Fully restored or newly engineered dashboard components

High-accuracy 3D scanned replacements

No sanding, bogging, repairing, or plastic welding needed

Consistent, repeatable production for workshops and restorers

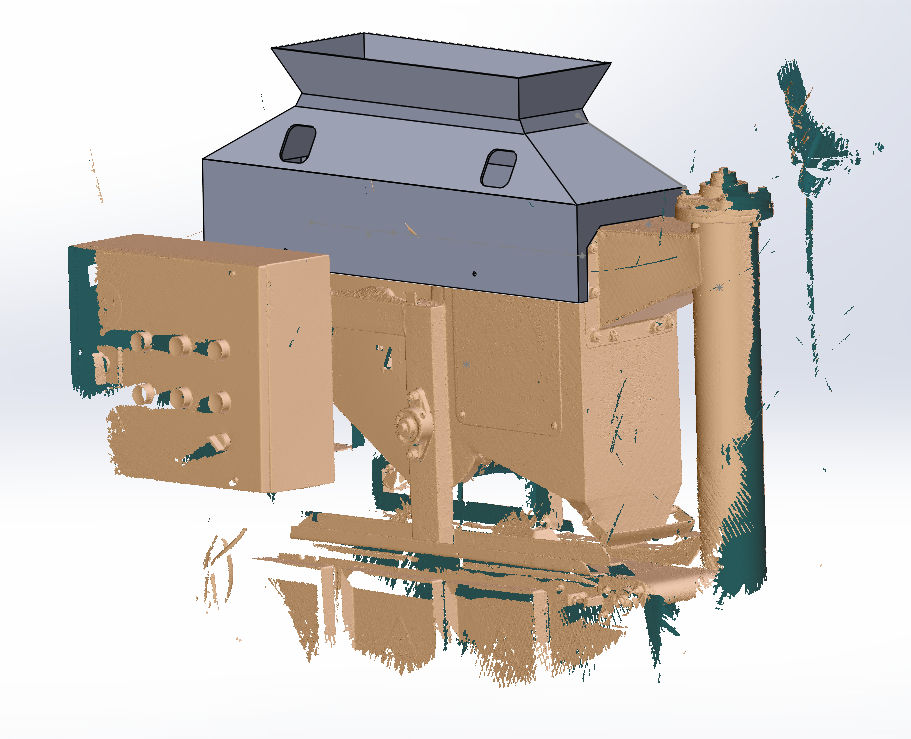

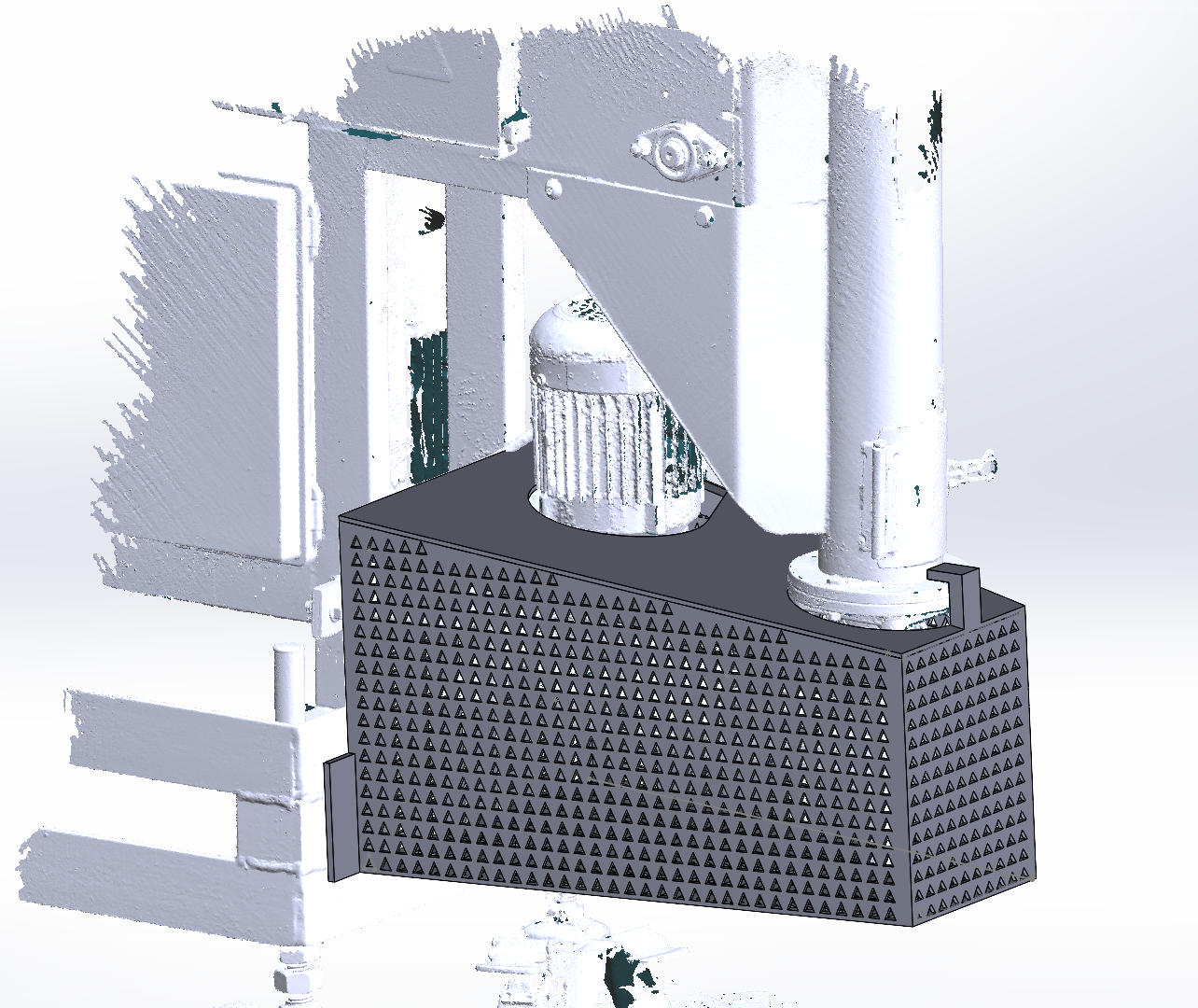

Machine & Safety Guarding (AS/NZS Compliant)

A client required urgent machine guarding after safety audits flagged several risks. We scanned the equipment, engineered compliant guarding, and manufactured the components rapidly using industrial-grade materials.

Why clients trust us:

Designed to meet Australian Machine Guarding Standards (AS 4024)

Fast turnaround through accurate 3D scanning

Proven experience in factory and industrial environments

Passed all final safety and risk assessment requirements

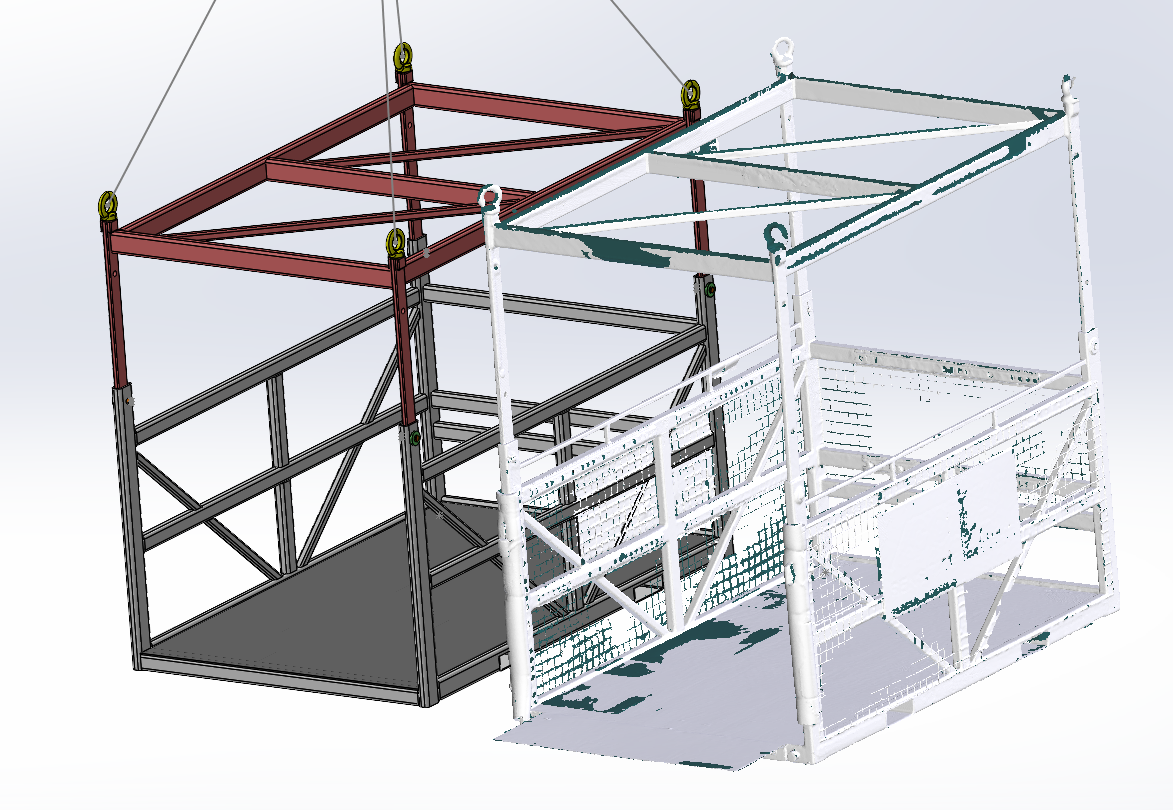

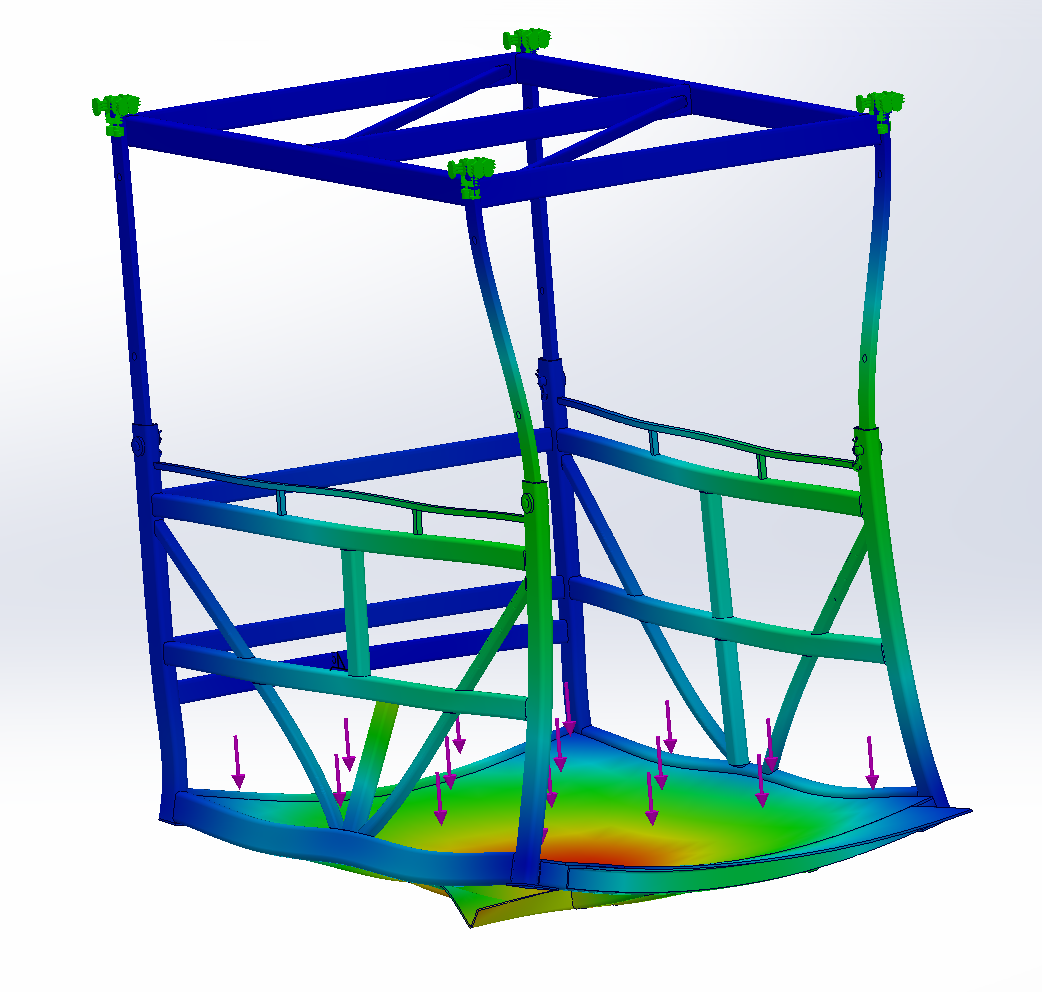

Structural Analysis & Reverse-Engineered Lifting Cage

This client required engineering documentation and certification for an existing lifting device as part of their JSA and pre-start safety requirements.

We scanned the entire structure, rebuilt the model with full nut-and-bolt accuracy, and prepared it for FEA structural simulation.

What we achieved:

Full 3D scan of the lifting cage

Engineering-ready CAD reconstruction

No repeated measurements or site revisits

Accurate model ideal for FEA, certification, and compliance

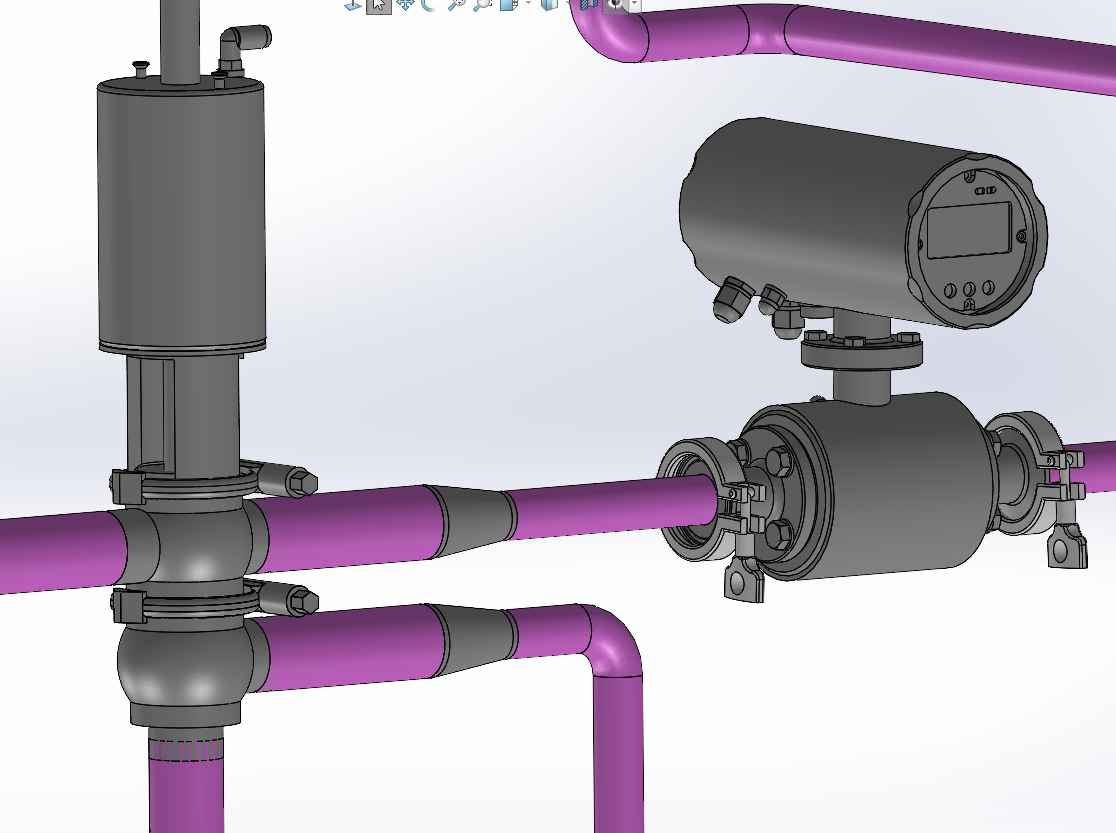

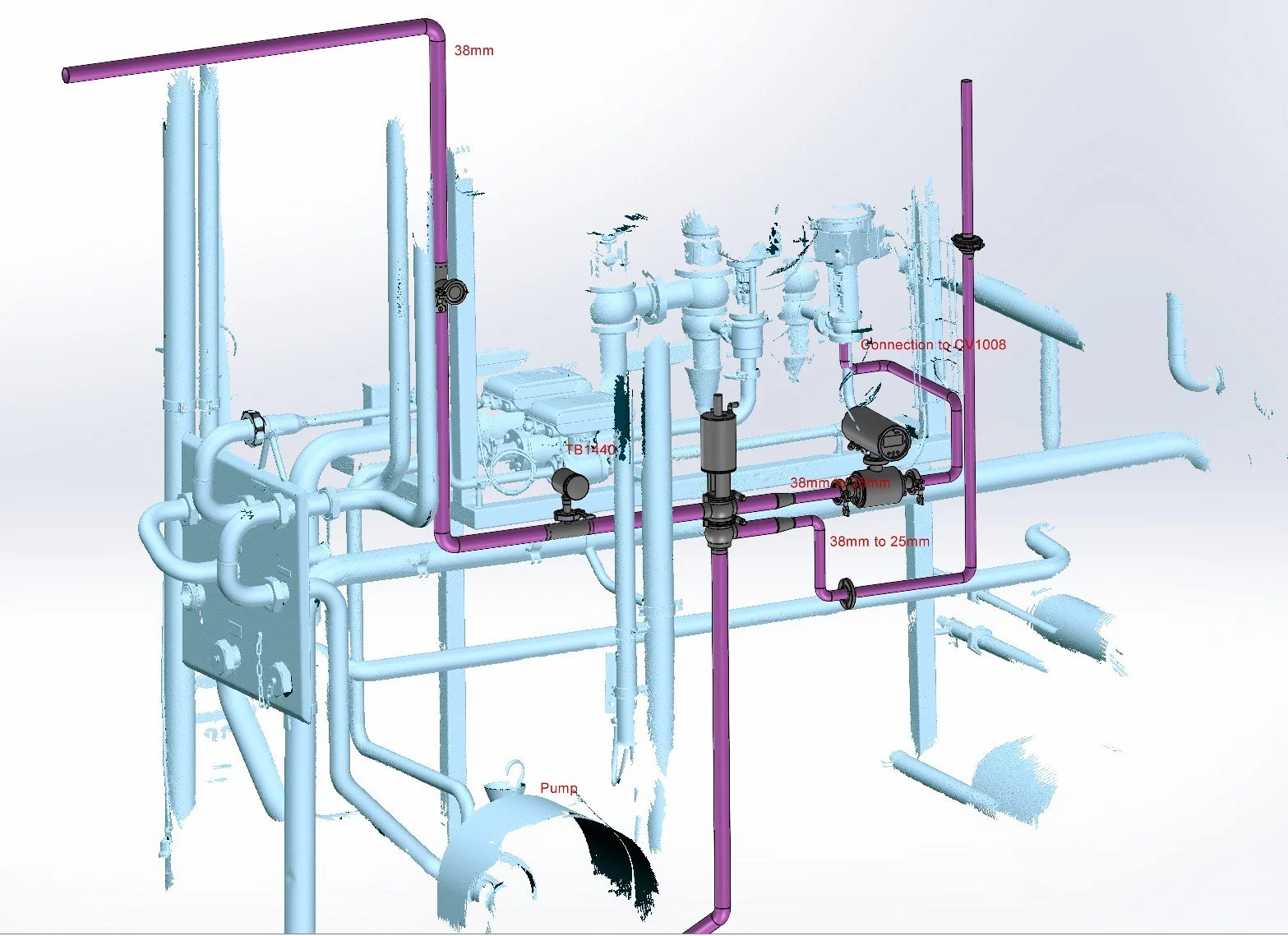

Piping & Routing (Food & Beverage / Dairy Industry)

Years of modifications left this client’s piping system in a “spaghetti mess.” Traditionally, fixing this requires weeks of manual measurement and guesswork.

Instead, we 3D scanned the area and produced a clean, accurate digital layout of pipework and instrumentation.

Results:

Visual overlay of the new pipe routing

Exact measurements for trades and engineers

Zero guesswork and fewer revisions

Rapid approval from manufacturing teams